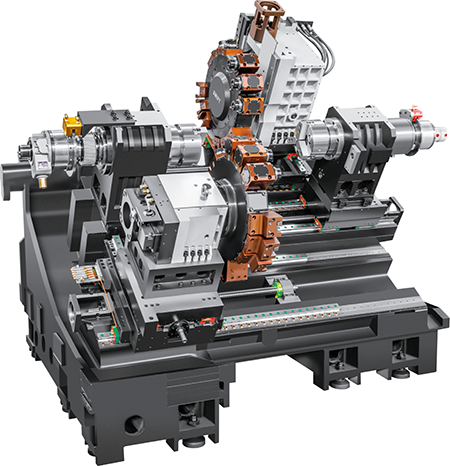

CNC Double Spindle Single Turret Turning Center SC Series

Produkt konfiguraasje

Features

De struktuer fan it haadlichaam, ynklusyf de basis, saddle, spindelkop, slide sit, sub-spindel, ensfh., is folslein makke fan

Meehanite casting, en wurdt dan annealed te elimineren stress te garandearjen lange-termyn krektens.

Hege-optreden servomotor driuwt direkt de bal skroef, en de bal skroef is foarspand

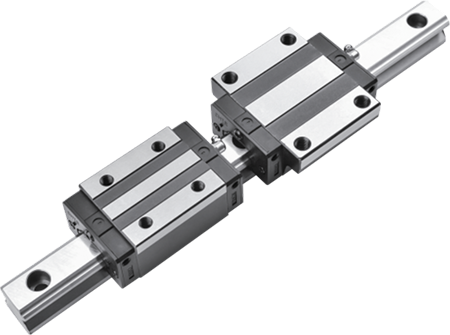

Alle assen oannimme lineêre rails fan rollertype.

De sub-spindel is foarsjoen fan in ynboude motor, dy't trochgeande ferwurking mooglik makket fan oerdracht fan wurkstik nei de

twadde proses.

De standert konfiguraasje omfiemet 0,001 ° kommando C-as indexing, en de opsje omfiemet contour ferwurkjen.

Technyske spesifikaasjes

| Projekt | CNC-460SC(360) | CNC-680SC(620) | CNC-860SC(800) | CNC-860SC (1900) | CNC-860SC(2900) | |

| Bed Frame | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is skuins op 30 °. | It bêd en de basis binne makke fan heechweardich getten izer, | ||||

| Ferwurkjen Range | Max. swing diameter oer bêd | 500 mm | 600 mm | 780 mm | 780 mm | 780 mm |

| Max. ferwurkjen diameter fan skiven | 400 mm | 400 mm | 650 mm | 650 mm | 650 mm | |

| Max. ferwurkjen diameter fan de koets | 400 mm | 400 mm | 500 mm | 500 mm | 500 mm | |

| Max. ferwurkjen lingte fan bal materiaal | 360 mm | 620 mm | 800 mm | 1900 mm | 2900 mm | |

| Max. bar diameter | Main: Ф45 mm | Main: Ф51mm | Main: Ф75 mm | Main: Ф75 mm | Main: Ф75 mm | |

| Reizgje | Max. X-as reis | 200 mm | 230 mm | 350 mm | 700 mm | 700 mm |

| Max. Z1 / Z2-as reis | 400/400 mm | 770/650 mm | 1050/900 mm | 2050/1900 mm | 3050/2900 mm | |

| Max. Y-as reis | ± 45 mm | ± 45 mm | ± 75 mm | ± 75 mm | ±75 | |

| Chuck grutte | 0-500 mm | 0-620 mm | 0-800 mm | 0-2060 mm | 0-3060 | |

| X/Z1/Z2/Y-as snelle snelheid | 20 m/min | 30 m/min | 18 m/min | 18 m/min | 18 m/min | |

| X / Z1 / Z2 / Y screw diameter / pitch | 32/10 mm | 40/10 mm | X: 50/80 mm | 5008/6312 mm | 5008/6312 mm | |

| X / Z1 / Z2 / Y lineêre gids breedte | 35 mm | 35 mm | 55 mm | 55 mm | 55 mm | |

| X-as servomotor | ß22 (rem) | ß12 (rem) | ß22 (rem) | ß22 (rem) | ß22 (rem) | |

| Z1/Z2 as servomotor | ß12/12 | β12/12 | B22/22 | β22/22 | β30/30 | |

| Y-as servomotor | ß12 | β12 | β12 | β12 | β12 | |

| Turret servo motor | 3N.m | 3N.m | 3N.m | 3N.m | 3N.m | |

| Power kop servo motor | β12 | β12 | β22 | β22 | β22 | |

| Krektens | X / Z1 / Y-as posisjonearring accuracy | ± 0,003 mm | ± 0,003 mm | ± 0,008 mm | ± 0.004/300 mm | ± 0.0041300 mm |

| X / Z1 / Y-as repeatability | ± 0,003 mm | ± 0,003 mm | ± 0.005 mm | ± 0.003/300 mm | ± 0.003/300 mm | |

| Spindle | Spindle taper | Haad: A2-5 | Haad: A2-6 | Haad: A2-8 | Haad: A2-8 | Haad: A2-8 |

| Spindle boring diameter | Main: Ф56mm | Main: Ф66 mm | Main: Ф88mm | Main: Ф88mm | Main: Ф88mm | |

| Max. spindle snelheid | Main: 4000 rpm | Main: 4000 rpm | Main: 2500 rpm | Main: 3000 rpm | Main: 3000 rpm | |

| Spindle servo motor macht | Main: 7.5/11KW | Main: 15/18.5KW | Main: 15KW | Main: 15KW | Main: 22KW | |

| Chuck / draaiende silinder | Main:6"/Sub:6" | Main:8"/Sub:6" | Main:10"/Sub:8" | Main:10"/Sub:8" | Main:10"/Sub:8" | |

| Power Head | 90° macht kop | ER25/4000rpm | ER25/3000 rpm | ER40/3000rpm | ER32/4000rpm | ER32/4000rpm |

| 0° macht kop | ER25/4000rpm | ER25/3000 rpm | ER40/3000rpm | ER32/4000rpm | ER32/4000rpm | |

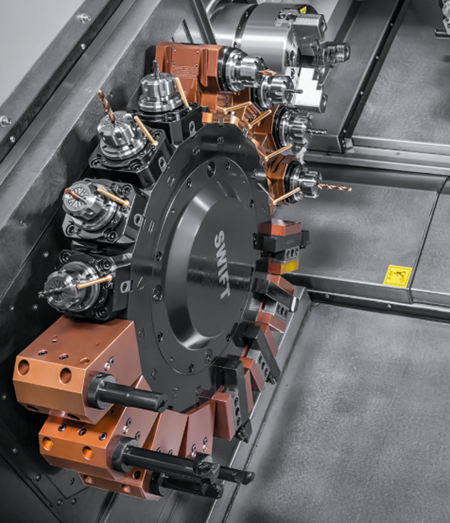

| Turret | Turret spesifikaasjes | BMT45/15 Stations | BMT55/12 Stations | BMT65/12 Stasjons | BMT65/12 Stasjons | BMT65/12 Stasjons |

| Tool holder spesifikaasjes | □20×20 | □20×20 | □25×25 | □25×25 | □25×25 | |

| Saai ark holder | Ф25 mm | Ф25 mm | Ф40 mm | Ф40 mm | Ф40 mm | |

| Oar | Totale macht | 44 kW | 38 kW | 56 kW | 56 kW | 70 kW |

| Machine tool netto gewicht | Oer 4900 kg | Oer 5500 kg | Oer 7700 kg | Oer 9700 kg | Oer 12200 kg | |

| Masinegrutte (lingte x breedte x hichte) | 2750 × 1700 × 1800 mm | 3100 × 1900 × 2000 mm | 6000 × 2300 × 2550 mm | 7000 × 2300 × 2550 mm | 8500 × 2300 × 2550 mm | |

Konfiguraasje Features

Spindle

Stypje hege-precision en swiere-duty cutting te fergrutsjen produktiviteit.

Turret

Ferbettert yndeksearring betrouberens en soarget foar hege rigidity.

Systeem

Standert FANUC F Oi-TF Plus CNC-systeem, hege ferwurkingsprestaasjes hege bestjoeringsnivo, heech gebrûksgemak.

Hege rigidity

Heavy-duty getten izeren basis en komponinten, sterke skokabsorption en hege stabiliteit.

Ball Screw

Skroef foarspanning, backlash en ferlinging fan temperatuerferheging wurde foarôf eliminearre.

Roller Linear Guide

Arc cutting, bevel cutting, en unifoarm oerflak textuur. Universele hege snelheid rotaasje.