GM5X-I 5-axis CNC Grinding Machine

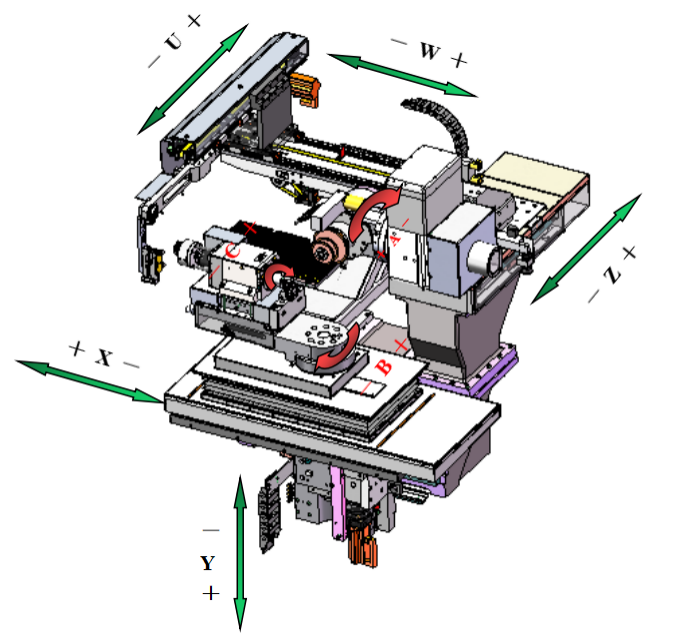

Main struktuer diagram fan masine

Applikaasje omfang

Dizze masine produsearret ein milling cutter en boren, geskikt foar it ferwurkjen fan hurde alloy en hege-snelheid stielen materialen.

Tool manufacturing en regrining syklusen

Standert einmills: grooving, backing, rake sharpening, bottom edge sharpening, digitalisearring, rerisping.

1. Technyske spesifikaasjes

| № | Ynhâld | Eask | Nûmer | Ienheid |

| 1.1 | Workpiece Ofmjittings | |||

| 1.1.1 | Clamping lingte | ≤ | 230 | mm |

| 1.1.2 | Clamping diameter | tusken | 2-20 | mm |

| 1.1.3 | Grinding lingte | ≤ | 150 | mm |

| 1.1.4 | Grinding diameter | tusken | 0,3-12 | mm |

| 1.2 | Grinding Spindle | |||

| 1.2.1 | Drive type | Akkuraat | direkte oandriuwing | - |

| 1.2.2 | Krêft | rated macht | 13.6 | kW |

| 1.2.3 | Cooling | Akkuraat | Oalje ôfkuolle | - |

| 1.2.4 | Faasje kontrôle fan grinding tsjil | Akkuraat | Stapleaze snelheid | - |

| 1.2.5 | Faasje | tusken | 0-10000 | rpm |

| 1.2.6 | Oantal spindle grinding hollen | Akkuraat | 2 | pcs |

| 1.3 | Grinding tsjil | |||

| 1.3.1 | Diameter | ≤ | 150 | mm |

| 1.3.2 | Maksimum oantal grinding tsjillen per spil | ≤ | 4 | pcs |

| 1.3.3 | Grinding tsjillen spindle diameter | Akkuraat | 25 | mm |

| 1.3.4 | Programma kontrolearre coolant oanbod | Akkuraat | Ja | - |

| 1.3.5 | Oantal coolant nozzles | ≥ | 3 | pcs |

| 1.4 | Workpiece clamping systeem | |||

| 1.4.1 | Klemsysteem | Akkuraat | Hydraulic, automatysk | - |

| 1.4.2 | Klemstang | Akkuraat | SCHAUBLIN W20 | - |

| 1.4.3 | Drive type | Akkuraat | direkte oandriuwing | - |

| 1.5 | As parameters | |||

| 1.5.1 | Type | Akkuraat | lineêr | - |

| 1.5.2 | X-as reis | ≤ | 280 | mm |

| 1.5.3 | Z-as reis | ≤ | 130 | mm |

| 1.5.4 | Y-as reis | ≤ | 230 | mm |

| 1.5.5 | XYZ-as resolúsje | Akkuraat | 0.0001 | mm |

| 1.5.6 | XYZ as snelheid | ≤ | 10 | m/min |

| 1.5.7 | A-as reis | ≤ | 360 | graad |

| 1.5.8 | A-as resolúsje | Akkuraat | 0.0001 | graad |

| 1.5.9 | A-as snelheid | ≤ | 300 | rpm |

| 1.5.10 | B-as reis | ± | 210 | graden |

| 1.5.11 | B-as snelheid | ≤ | 12 | rpm |

| 1.6 | Laden en lossen systeem | |||

| 1.6.1 | Laden en lossen systeem | Akkuraat | Truss type robotyske earm | - |

| 1.6.2 | Oantal trays | Akkuraat | 2 | pcs |

| 1.6.3 | Automatysk laden en lossen wurkstik diameter | Tusken | 2-12 | mm |

| 1.6.4 | Automatysk laden en lossen wurkstik lingte | ≤ | 40-200 | mm |

| 1.6.5 | Maksimum oantal workpieces | ≤ | 300 | pcs |

| 1.6.6 | Software | Akkuraat | Ja | - |

| 1.7 | Oare komponinten | |||

| 1.7.1 | Mooglikheid om workpieces op masine ark te detektearjen | Akkuraat | Ja | - |

| 1.7.2 | Sintraal automatysk lubrication systeem | Akkuraat | Ja |

|

| 1.7.3 | Tricolor sinjaal lamp | Akkuraat | Ja | - |

| 1.8 | Fakultatyf | |||

| 1.8.1 | Oalje mist skieding apparatuer | Akkuraat | Fakultatyf | - |

| 1.9 | Kontrôle | |||

| 1.9.1 | Control systeem | Akkuraat | NUCN-IM8+ | - |

| 1.9.2 | Operaasje paniel | Akkuraat | Touch skerm | - |

| 1.9.3 | Digitale kontrôle as | Akkuraat | Ja | - |

| 1.9.4 | Kleur display | Akkuraat | Ja | - |

| 1.9.5 | Display Grutte | Akkuraat | 19 | inch |

| 1.10 | Tool grinding software module | |||

| 1.10.1 | Ienfâldige frezen | Akkuraat | Ja | - |

| 1.10.2 | Ienfâldige oefeningen | Akkuraat | Ja | - |

| 1.10.3 | Probe automatyske deteksjemodus | Akkuraat | Ja | - |

| 1.11 | Equipment elektryske parameters | |||

| 1.11.1 | Voltage | Akkuraat | 380±10% | V |

| 1.11.2 | Frekwinsje | Akkuraat | 50±10% | Hz |

| 1.11.3 | Krêft | ≤ | 25 | KW |

| 1.12 | Ofmjittings | |||

| 1.12.1 | Lingte | ≤ | 2 000 | mm |

| 1.12.2 | Breedte | ≤ | 2 800 | mm |

| 1.12.3 | Hichte | ≤ | 2 200 | mm |

| 1.12.4 | Kwaliteit | ≤ | 4 750 | kg |

2. Standert konfiguraasje list

| № | Ynhâld | Model | Merk | Nûmer | ||

| 2.1 | Machine ark | |||||

| 2.1.1 | X-as konfiguraasje | |||||

| 2.1.1.1 | - Screw rod | Oanpast | NSK | 1 stk | ||

| 2.1.1.2 | - Spoar | 1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 stk | ||

| 2.1.2 | Y-as konfiguraasje | |||||

| 2.1.2.1 | - Screw rod | Oanpast | NSK | 1 stk | ||

| 2.1.2.2 | - Spoar | 1×MR35-C2-600-20-20-G2-V2+MRK | SCHNEEBERGER | 2 stk | ||

| 2.1.3 | Z-as konfiguraasje | |||||

| 2.1.3.1 | - Screw rod | Oanpast | NSK | 1 stk | ||

| 2.1.3.2 | - Spoar | 1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL | SCHNEEBERGER | 2 stk | ||

| 2.1.4 | A-as konfiguraasje | |||||

| 2.1.4.1 | - Hoek encoder | ECN113 | HEIDENHAIN | 1 stk | ||

| 2.1.4.2 | - Direkte oandriuwing motor | MSP-1000-2-002-158 | HIWIN | 1 stk | ||

| 2.1.5 | B-as draaitafel | Oanpast | GuTian | 1 stk | ||

| 2.1.6 | Permaninte magneet dûbele kop elektryske spindle | Rated macht 7.1KW | Chuangyun | 1 stk | ||

| 2.1.7 | Trije assen truss manipulator | - | Chuangyun | 1 stk | ||

| 2.1.8 | Tray | 148-LP-D4 | Chuangyun | 2 stk | ||

| 2.1.9 | Tray | 148-LP-D6 | Chuangyun | 2 stk | ||

| 2.1.10 | Tray | 148-LP-D8 | Chuangyun | 2 stk | ||

| 2.1.11 | Klemme kaak | D0,5-3,2/D3,0-7,0/D7-13 | Chuangyun | 1 set | ||

| 2.1.12 | V-blok mei hege presyzje | (3-5) | Chuangyun | 1 stk | ||

| 2.1.13 | V-blok mei hege presyzje | (5-7) | Chuangyun | 1 stk | ||

| 2.1.14 | V-blok mei hege presyzje | (6-12) | Chuangyun | 1 stk | ||

| 2.1.15 | Collet | D4W20 (80-00004) | SCHAUBLIN | 1 stk | ||

| 2.1.16 | Sonde | TS150 | HEIDENHAIN | 1 stk | ||

| 2.1.17 | Slijpwielstang (lang) | 119×∅31.75×∅96mm | Chuangyun | 1 stk | ||

| 2.1.18 | Slijpwielstang (koart) | 87×∅31.75×∅96mm | Chuangyun | 1 stk | ||

| 2.1.19 | Air conditioning | - | YUEDE | 1 stk | ||

| 2.1.20 | Tricolor sinjaal lamp | DC24V | Schneider | 1 stk | ||

| 2.1.21 | Flowmeter | SI5000 | IFM | 1 stk | ||

| 2.1.22 | Drive spesifike Netzteil | 15 kW | NEWCOM | 1 stk | ||

| 2.1.23 | Elektromagnetyske klep groep | M4GE280R-CX-E20D-5-3 | CKD | 1 set | ||

| 2.1.24 | X, Y, Z-as automatysk smeersysteem | - | Taiwan | 1 set | ||

| 2.2 | CNC systeem konfiguraasje | |||||

| 2.2.1 | BOXPC | IMPC00S/P1 | Newcon | 1 stk | ||

| 2.2.2 | Power filter | AGOFIL024A | NUM | 1 stk | ||

| 2.2.3 | Power filter | AGOFIL001S | NUM | 1 stk | ||

| 2.2.4 | Ferset | AGORES008 | NUM | 1 stk | ||

| 2.2.5 | Systeem wichtichste macht oanbod | MDLL3015N00AN0I | NUM | 1 stk | ||

| 2.2.6 | Servo bestjoerder | MDLUX021B1CAN0I | NUM | 4 stk | ||

| 2.2.7 | B-as servomotor | ZLS1002-H60-D3M1-NNSB-D16E40 | NUM | 1 stk | ||

| 2.2.8 | A-as motor | MSP-1000-2-002-158 | NUM | 1 stk | ||

| 2.2.9 | Y-as servomotor | ZLS1454-H30-DCM1-SNSB-D24E50 | NUM | 1 stk | ||

| 2.2.10 | X/Z-as servomotor | ZLS1153-H30-D3M1-NNSB-D19E40 | NUM | 2 stk | ||

| 2.2.11 | U / W as servo driver | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 2 stk | ||

| 2.2.12 | V-as servomotor | ZLS0754-H60-D2M1-SNSB-D14E30 | NUM | 1 stk | ||

| 2.2.13 | Koppeler | EX-1100 | Newcon | 1 stk | ||

| 2.2.14 | Ynfier | EX-210H | Newcon | 2 stk | ||

| 2.2.15 | Utfier | EX-310H | Newcon | 2 stk | ||

| 2.2.16 | Analoge ynfier module | EX-4054 | Newcon | 1 stk | ||

| 2.2.17 | Terminator | EX-TRE01 | Newcon | 1 stk | ||

| 2.2.18 | Operaasje paniel | IMOP4106/H | Newcon | 1 stk | ||

| 2.2.19 | NCK | IM8+ | Newcon | 1 stk | ||

| 2.2.20 | NCK | IMSO100006 | Newcon | 1 stk | ||

| 2.2.21 | NCK | IMSO100008 | Newcon | 1 stk | ||

| 2.2.22 | NCK | IMSO100012 | Newcon | 1 stk | ||

| 2.2.23 | NCK | IMPA100586 | Newcon | 1 stk | ||

| 2.2.24 | NCK | IMSO100373 | Newcon | 1 stk | ||

| 2.2.25 | NCK | IMSO100375 | Newcon | 1 stk | ||

| 2.2.26 | NCK | IMSO100335 | Newcon | 1 stk | ||

| 2.2.27 | NCK | IMSO100519 | Newcon | 1 stk | ||

| 2.2.28 | NCK | IMSO100392 | Newcon | 1 stk | ||

| 2.2.29 | NCK | IMSO100331 | Newcon | 1 stk | ||

| 2.2.30 | NCK | IMSO100535 | Newcon | 1 stk | ||

| 2.2.31 | NCK | IMSO100520 | Newcon | 1 stk | ||

| 2.2.32 | NCK | IMSO100560 | Newcon | 1 stk | ||

| 2.3 | Standert konfiguraasje fan ark grinding software | |||||

| 2.3.1 | Ienfâldige frezen | Chuangyun sels ûntwikkele | 1 stk | |||

| 2.3.2 | Ienfâldige drill | Chuangyun sels ûntwikkele | 1 stk | |||

| 2.3.3 | 3D-botsingskontrôle mei 3D-masinesimulaasje | Chuangyun sels ûntwikkele | 1 stk | |||

| 2.3.4 | 3D ark simulaasje | Chuangyun sels ûntwikkele | 1 stk | |||

| 2.3.5 | Probe automatyske deteksje | Chuangyun sels ûntwikkele | 1 stk | |||