Servo Turret Tailstock T Series

Produkt konfiguraasje

Machine funksjes

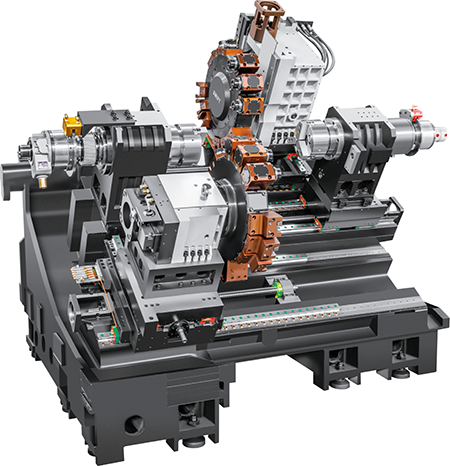

Hege rigidity, swiere snijden, en hege stabiliteit: It oannimt in yntegraal getten hellend bêd, in 30 ° hellende bêdstruktuer, en in dikke ribûntwerp om ferfoarming en thermyske deformaasje te minimalisearjen.

Hege presyzje en hege dynamyske reaksje: Hege presys kogellagers wurde brûkt oan 'e foar- en efterkant om hege spindle-stijfheid en ekstreem hege spindle-rotaasje-krektens te berikken.

Spindel servo-ienheid, hege presyzje en handich ûnderhâld.

Hege effisjinsje: De maksimale spindle snelheid is 4500rpm / min, en de flugge beweging kin berikke 30m / min.

Technyske spesifikaasjes

| Projekt |

| CNC-520T(460) | CNC-520T(520) | CNC-650T(700) | |

| Bed Frame | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is 40 ° hellend. | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is skuins op 30 °. | |||

| Ferwurking | Max. swing diameter oer bêd | 580 mm | 580 mm | 600 mm | 600 mm |

| Max. ferwurkjen diameter fan skiven | 400 mm | 400 mm | 350 mm | 400 mm | |

| Max. ferwurkjen diameter fan de koets | 280 mm | 280 mm | 350 mm | 400 mm | |

| Max. ferwurkjen lingte fan bar | 460 mm | 460 mm | 520 mm | 700 mm | |

| Max. bar diameter | f45mm | f51mm | f51mm | ||

| Reizgje | Max.X-as travel | 230 mm | 240 mm | 220 mm | 220 mm |

| Max. Z-as reis | 500 mm | 500 mm | 550 mm | 770mm | |

| X / z-as rappe snelheid | 30 min | 30 m/min | 24 m/min | 25m / min | |

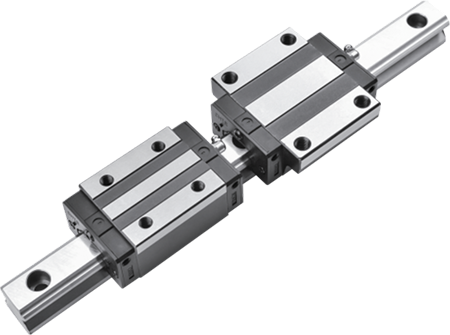

| X / Z screw diameter / pitch | 32/10 mm | 32/10 mm | X: 40/10mm | 40/10 mm | |

| X / Z lineêre gids breedte | 35 mm | 35 mm | 45 mm | 35 mm | |

| X-as servomotor | β12 (rem) | β12 (rem) | β12 (rem) | β12 (rem) | |

| Z-as servomotor | β12 | β12 | β12 | β12 | |

| Turret servo motor | 3N.m | 3N.m | 3N.m | 3N.m | |

| Krektens | X / Z-AXS-posysjonearjende krektens | ± 0,003 mm | ± 0,003 mm | ± 0,003 mm | ± 0,003 mm |

| X / Z-as repeatability | ± 0,003 mm | ± 0,003 mm | ± 0,003 mm | ± 0,003 mm | |

| Ferpleatse tailstock | Spesifikaasjes fan tailstock Sleeve | Moai #5 | Moai #5 | Mohs # 5/80 | Moai #5 |

| Tailstock sleeve reis | 40-460 mm | 40-460 mm | 50-600mm | 50-800mm | |

| Tailstock druk berik | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | |

| Tailstock moving metoade | Programmable Hydraulic | Programmable Hydraulic | Programmable Hydraulic | Saddle dreaun, | |

| Spindle | Spindle taper | A2-5 | A2-6 | A2-6 | A2-6 |

| Spindle boring diameter | ф56mm | f75mm | f75mm | f75mm | |

| Max. spindle snelheid | 6000 rpm | 4500 rpm | 4500 rpm | 4000rpm | |

| Spindle servo motor macht | 7,5/11 KW | 1 kW | 11/15JV | 11/15JV | |

| Chuck / draaiende silinder | 6 "/6 " | 8"/8" | 8 "/ 8时 | 8" | |

| Turret | Turret spesifikaasjes | 80center heech / | 80center heech / | 100Center heech / | 100Center heech / |

| Grutte snijkop | 340 | 340 | 420 | 380 | |

| Tool holder spesifikaasjes | □25×25 | □25×25 | □25×25 | □25×25 | |

| Saai ark holder | ф40mm | ф40mm | ф40mm | ф40mm | |

| Oar | Totale kapasiteit | 15 kW | 20 KW | 20 KW | 20 KW |

| Machine tool netto gewicht | Oer 4500 kg | Oer 4500K | Oer 5000 kg | Sawat 5700 kg | |

| Machinegrutte (lingte × breedte × hichte) | 2600 × 1700 × 1900mm | 2600 × 1700 × 1900mm | 2800 × 2000 × 1900mm | 2800 × 1800 × 1800mm | |

| Projekt | CNC-860T (1000) | CNC-860T (2000) | CNC-860T(3000) | |

| Bed Frame | It bêd en basis binne makke fan getten izer fan hege kwaliteit, en it bêd is yn 40 ° ôfslien. | |||

| Ferwurking | Max. swing diameter oer bêd | 780 mm | 7800m | 780 mm |

| Max. ferwurkjen diameter fan skiven | 600 mm | 600 mm | 600 mm | |

| Max. ferwurkjen diameter fan de koets | 500mmmm | 500mmm | 500mmm | |

| Max. ferwurkjen lingte fan bar | 1000 mm | 2000 mm | 3000 mm | |

| Max. bar diameter | f75mm | f75mm | f75mm | |

| Reizgje | Max.X-as travel | 350 mm | 350 mm | 350 mm |

| Max. Z-as reis | 1050 mm | 2050mm | 3050mm | |

| X / z-as rappe snelheid | 18 m/min | 18 m/min | 15m / min | |

| X / Z screw diameter / pitch | X50/08mm | X: 50 / 08mm | X: 50 / 08mm | |

| X / Z lineêre gids breedte | 55 mm | 55 mm | 55 mm | |

| X-as servomotor | P22 (Brake) | β22 (Brake) | β22 (Brake) | |

| Z-as servomotor | β22 | β22 | β30 | |

| Turret servo motor | 3N.m | 3N.m | 3N.m | |

| Krektens | X / Z-AXS-posysjonearjende krektens | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm |

| X / Z-as repeatability | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | |

| Ferpleatse tailstock | Spesifikaasjes fan tailstock Sleeve | Moai #5 | Moai #5 | Moai #5 |

| Tailstock sleeve reis | ф150 / 200mm | ф150 / 200mm | ф150 / 200 | |

| Tailstock druk berik | 5-30 kg/cm² | 5-30 kg/cm² | 5-30kg / cm | |

| Tailstock moving metoade | Programmable Hydraulic | Programmable Hydraulic | Programmable Hydraulic | |

| Spindle | Spindle taper | A2-8 | A2-8 | A2-8 |

| Spindle boring diameter | ф88mm | ф8bmm | ф88mm | |

| Max. spindle snelheid | 2500 rpm | 2500 rpm | 2500 rpm | |

| Spindle servo motor macht | 15 kW | 18,5 kW | 22 kW | |

| Chuck / draaiende silinder | 10 "/ 10" | 10 "/ 10" | 10 "/ 10" | |

| Turret | Turret spesifikaasjes | 100Center heech / | 125CENTER HIGH / | 125CENTER HIGH / |

| Grutte snijkop | 440 | 440 | 440 | |

| Tool holder spesifikaasjes | □32×32 | □32×32 | □32×32 | |

| Saai ark holder | ф50mm | ф50mm | ф50mm | |

| Oar | Totale kapasiteit | 27 kW | 31kw | 35 kW |

| Machine tool netto gewicht | Oer 7700 kg | Oer 9700 kg | Om 18500 kg | |

| Machinegrutte (lingte × breedte × hichte) | 6000 × 2300x2550mm | 7000 × 2300 × 2550 mm | 7500 × 2500 × 2550mm | |

| Projekt | CNC-960T (1000) | CNC-960T (2000) | CNC-960T (3000) | |

| Bed Frame | It bêd en basis binne makke fan getten izer fan hege kwaliteit, en it bêd is yn 40 ° ôfslien. | |||

| Ferwurking | Max. swing diameter oer bêd | 880mm | 880mm | 880mm |

| Max. ferwurkjen diameter fan skiven | 600 mm | 600 mm | 600 mm | |

| Max. ferwurkjen diameter fan de koets | 600 mm | 600 mm | 600 mm | |

| Max. ferwurkjen lingte fan bar | 1000 mm | 2000 mm | 3000 mm | |

| Max. bar diameter | f91mm | φ91mm | φ91mm | |

| Reizgje | Max.X-as travel | 350 mm | 350 mm | 350 mm |

| Max. Z-as reis | 1050 mm | 2050mm | 3050mm | |

| X / z-as rappe snelheid | 18 m/min | 18 m/min | 15m / min | |

| X / Z screw diameter / pitch | X: 50 / 08mm | X: 50 / 08mm | X: 50 / 08mm | |

| X / Z lineêre gids breedte | 55 mm | 55 mm | 55 mm | |

| X-as servomotor | β22 (Brake) | β22 (Brake) | β22 (Brake) | |

| Z-as servomotor | β22 | β22 | β30 | |

| Turret servo motor | 3N.m | 3N.m | 3nm | |

| Krektens | X / Z-AXS-posysjonearjende krektens | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm |

| X / Z-as repeatability | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | |

| Ferpleatse tailstock | Spesifikaasjes fan tailstock Sleeve | Moai #5 | Moai #5 | Moai #5 |

| Tailstock sleeve reis | ф150 / 200mm | ф150 / 200mm | ф150 / 200mm | |

| Tailstock druk berik | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | |

| Tailstock moving metoade | Programmable Hydraulic | Programmable Hydraulic | Programmable Hydraulic | |

| Spindle | Spindle taper | A2-11 | A2-11 | A2-11 |

| Spindle boring diameter | ф105mm | ф105mm | ф105mm | |

| Max. spindle snelheid | 2200 rpm | 2200 rpm | 2200 rpm | |

| Spindle servo motor macht | 15 kW | 22 kW | 22 kW | |

| Chuck / draaiende silinder | 12 "/ 12 " | 12 "/ 12 " | 12 "/ 12 " | |

| Turret | Turret spesifikaasjes | 125CENTER HIGH / | 125CENTER HIGH / | 125CENTER HIGH / |

| Grutte snijkop | 440 | 440 | 440 | |

| Tool holder spesifikaasjes | □32×32 | □32×32 | □32×32 | |

| Saai ark holder | ф50mm | ф50mm | ф50mm | |

| Oar | Totale kapasiteit | 27 kW | 35 kW | 35 kW |

| Machine tool netto gewicht | Oer 8200 kg | Oer 10200 kg | Oer 12700 kg | |

| Machinegrutte (lingte × breedte × hichte) | 6000 × 2300x2550mm | 7000 × 2300 × 2550 mm | 8500 × 2300 × 2550 mm | |

Konfiguraasje Features

Spindle

Stypje hege-precision en swiere-duty cutting te fergrutsjen produktiviteit.

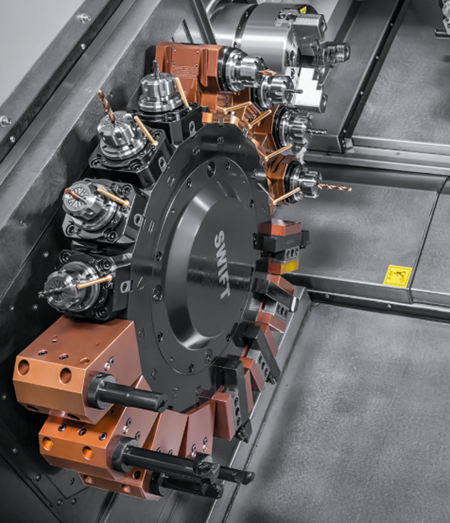

Turret

Ferbettert yndeksearring betrouberens en soarget hege rigidity.

Systeem

Standert FANUC F Oi-TF Plus CNC Systeem, hege ferwurkingsprestaasjes hege operaasje rate, hege gemak fan gebrûk.

Hege rigidity

Heavy-duty CastIron Base En Components, Sterke shock absorption en hege stabiliteit.

Ball Screw

Skroef foarspanning, backlash en ferlinging fan temperatuerferheging wurde foarôf eliminearre.

Roller Linear Guide

Arc cutting, bevel cutting, en unifoarm oerflak textuur. Universele hege snelheid rotaasje.