Turning Center TMC Series

Produkt konfiguraasje

Machine funksjes

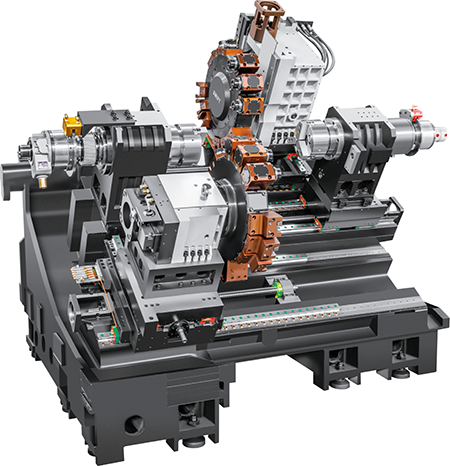

Hege rigiditeit, swiere snijden, hege stabiliteit: yntegreare cast slant bed, flatbed, 45 ° hellend spoar, en dikke ribbenûntwerp om ferfoarming en termyske ferfoarming te minimalisearjen.

Hege presyzje, hege dynamyske reaksje: NSK P4-kogellagers mei hege presyzje wurde foar en efter brûkt om hege rigiditeit en hege spindelrotaasje-krektens te berikken, De spindelservo-ienheid hat hege presyzje en handich ûnderhâld.

Hege effisjinsje: De maksimale snelheid fan 'e haadas is 6000rpm / min, en de rappe beweging kin 24m / min berikke. Troch de konfiguraasje fan it nije generaasje CNC-systeem fan Taiwan, wurdt XC-asferbining-ynterpolaasje realisearre, en wurdt de firtuele Y-asfunksje realisearre.

Technyske spesifikaasjes

| Projekt | CNC-460TMC | CNC-520TMC | CNC-680TMC | CNC-860TMC(1000) | CNC-860TMC(1500) | |

| Bed Frame | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is skuord op 40 °. | It bêd en de basis binne makke fan heechweardich getten izer. 30° hellend bed | It bêd en de basis binne makke fan heechweardich getten izer. 45 hellend bed | |||

| Ferwurkjen Range | Max. swing diameter oer bêd | 540 mm | 600 mm | 600 mm | 780 mm | 780 mm |

| Max. ferwurkjen diameter fan skiven | 360 mm | 320 mm | 400 mm | 650 mm | 650 mm | |

| Max. ferwurkjen diameter fan de koets | 280 mm | 320 mm | 400 mm | 500 mm | 500 mm | |

| Max. ferwurkjen lingte fan bar | 400 mm | 480 mm | 680 mm | 900 mm | 1400 mm | |

| Max. bar diameter | f45mm | f51mm | f51mm | f75mm | f75mm | |

| Travel Feed | Max. X-as reis | 220 mm | 220 mm | 230 mm | 350 mm | 350 mm |

| Max. Z-as reis | 470 mm | 520 mm | 750 mm | 1050 mm | 1550 mm | |

| Max. Y-as reis | ± 35 mm | ± 45 mm | ± 45 mm | ± 75 mm | ± 75 mm | |

| X/Z/Y-as snelle snelheid | 30 m/min | 30 m/min | 30 m/min | 16 m/min | 16 m/min | |

| X / Z / Y screw diameter / pitch | 32/10 mm | X: 40/10 mm | 40/10 mm | X: 50/08 mm | X: 50/08 mm | |

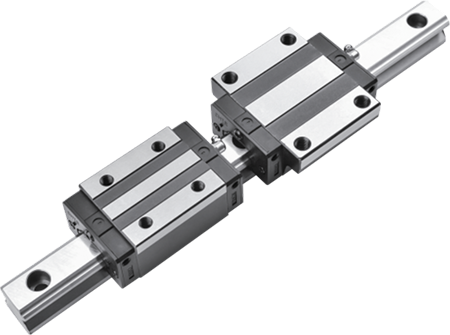

| X / Z lineêre gids breedte | 35 mm | 45 mm | 35 mm | 55 mm | 55 mm | |

| X-as servomotor | β12 (Rem) | β12 (Rem) | β12 (Rem) | β22 (Rem) | β22 (Rem) | |

| Z-as servomotor | β12 | β12 | β12 | β22 | β22 | |

| Y-as servomotor | β8(Brem) | β12 (Rem) | β12 (Rem) | β22 | β22 | |

| Servo turret motor | 3N.m | 3N.m | 3N.m | 1 kW | 1 kW | |

| Power kop motor | β12 | β12 | β12 | β22 | β22 | |

| Krektens | X / Z-as posisjonearring accuracy | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm |

| X / Z-as repeatability | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | |

| Moving Tailstock | Tailstock sleeve spesifikaasjes | Moai #5 | Moai #5 | Moai #5 | Moai #5 | Moai #5 |

| Tailstock reis | 40-460 mm | 50-600 mm | 0-790 mm | ф150/200 mm | ф150/200 mm | |

| Tailstock druk berik | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | |

| Tailstock moving metoade | Programmierbare hydraulyske | Programmierbare hydraulyske | Saddle dreaun, | (Hardway) Hydraulic oandreaun | ||

| Spindle | Spindle taper | A2-5 | A2-6 | A2-6 | A2-8 | A2-8 |

| Spindle boring diameter | f56mm | f66mm | f66mm | f88mm | f88mm | |

| Max. Spindle snelheid | 6000 rpm | 4500 rpm | 4500 rpm | 2500 rpm | 2500 rpm | |

| Spindle motor macht | 7,5/11 KW | 11 kW | 11/15 KW | 15 kW | 15 kW | |

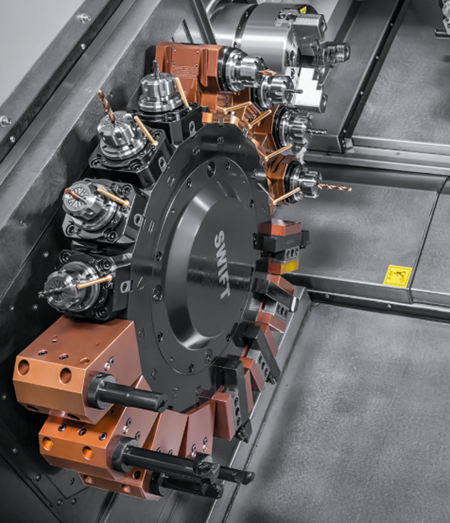

| Servo-oandreaune turret | BMT40/12 Stasjons | BMT55/12 Stations | BMT55/12 Stations | BMT65/12 Stasjons | BMT65/12 Stasjons | |

| Turret | Tool skiif grutte | 240 | 330 | 330 | 380 | 380 (hurde rail) |

| Tool holder spesifikaasjes | □20×20 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Saai ark holder | ф25 mm | f32mm | f32mm | f40mm | f40mm | |

| 0 graden side freeskop (1 stasjon) | ER20/3000 rpm | ER32/3000rpm | ER32/3000rpm | ER40/3000rpm | ER40/3000rpm | |

| 90 graden side freeskop (1 stasjon) | ER20/3000 rpm | ER32/3000rpm | ER32/3000rpm | ER40/3000rpm | ER40/3000rpm | |

| Oar | Totale kapasiteit | 22 kW | 26 kW | 26 kW | 34KW | 34KW |

| Machine tool netto gewicht | Oer 3800 kg | Oer 4000 kg | Oer 5000 kg | Oer 7000 kg | Oer 7800 kg | |

| Machine grutte (lengte × breedte × hichte) | 2600×1700×1950 | 2800×1700×2000 | 2900×2000×2200 | 6000 × 2300 × 2550 | 6500×2300×2550 | |

| Projekt | CNC-860TMC(2000) | CNC-860TMC(3000) | CNC-960TMC(1000) | CNC-960TMC(1500) | CNC-960TMC(2000) | CNC-960TMC(3000) | |

| Bed Frame | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is 45 ° hellend. | It bêd en de basis binne makke fan heechweardich getten izer, en it bêd is skuord op 45 °. | |||||

| Ferwurkjen Range | Max. swing diameter oer bêd | 780 mm | 780 mm | 880 mm | 880 mm | 880 mm | 880 mm |

| Max. ferwurkjen diameter fan skiven | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | 650 mm | |

| Max. ferwurkjen diameter fan de koets | 500 mm | 500 mm | 600 mm | 600 mm | 600 mm | 600 mm | |

| Max. ferwurkjen lingte fan bar | 1900 mm | 2900 mm | 900 mm | 1400 mm | 1900 mm | 2900 mm | |

| Max. bar diameter | f75mm | f75mm | f91mm | f91mm | f91mm | f91mm | |

| Travel Feed | Max. X-as reis | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm | 350 mm |

| Max. Z-as reis | 2050 mm | 3050 mm | 1050 mm | 1550 mm | 2050 mm | 3050 mm | |

| Max. Y-as reis | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | ± 75 mm | |

| X/Z/Y-as snelle snelheid | 16 m/min | 16 m/min | 16 m/min | 16 m/min | 16 m/min | 16 m/min | |

| X / Z / Y screw diameter / pitch | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | X: 50/08 mm | |

| X / Z lineêre gids breedte | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | 55 mm | |

| X-as servomotor | β22 (Rem) | β22 (Rem) | β22 (Rem) | β22 (Rem) | α22 (Rem) | α22 (Rem) | |

| Z-as servomotor | β22 | β22 | β12 (Rem) | β12 (Rem) | α12 (Rem) | α12 (Rem) | |

| Y-as servomotor | β22 | β22 | β22 | β22 | β22 | β22 | |

| Servo turret motor | 1 kW | 1 kW | 1 kW | 1 kW | 1 kW | 1 kW | |

| Power kop motor | β22 | β22 | β22 | β22 | β22 | β22 | |

| Krektens | X / Z-as posisjonearring accuracy | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm |

| X / Z-as repeatability | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | ± 0.003/300 mm | |

| Moving Tailstock | Tailstock sleeve spesifikaasjes | Moai #5 | Moai #5 | Moai #5 | Moai #5 | Moai #5 | Moai #5 |

| Tailstock reis | ф150/200 mm | ф150/200 mm | ф150/200 mm | ф150/200 mm | ф150/200 mm | ф150/200 mm | |

| Tailstock druk berik | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | 5-30 kg/cm² | |

| Tailstock moving metoade | (Hardway)Hydraulysk oandreaun | (Hardway)Hydraulysk oandreaun | |||||

| Spindle | Spindle taper | A2-8 | A2-8 | A2-11 | A2-11 | A2-11 | A2-11 |

| Spindle boring diameter | f88mm | f88mm | ф105 mm | ф105 mm | ф105 mm | ф105 mm | |

| Max. Spindle snelheid | 2500 rpm | 2500 rpm | 2200 rpm | 2200 rpm | 2200 rpm | 2200 rpm | |

| Spindle motor macht | 22 kW | 30 kW | 15 kW | 15 kW | 22 kW | 30 kW | |

| Servo-oandreaune turret | BMT65/12 Stasjons | BMT65/12 Stasjons | BMT65/12Stations | BMT65/12 Stasjons | BMT65/12 Stasjons | BMT65/12 Stasjons | |

| Turret | Tool skiif grutte | 380 (hurde rail) | 380 (hurde rail) | 380 (hurde rail) | 380 (hurde rail) | 380 (hurde rail) | 380 (hurde rail) |

| Tool holder spesifikaasjes | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 | |

| Saai ark holder | f40mm | f40mm | f40mm | f40mm | f40mm | f40mm | |

| 0 graden side freeskop (1 stasjon) | ER40/4000rpm | ER40/4000rpm | ER40/3000rpm | ER40/3000rpm | ER40/4000rpm | ER40/4000rpm | |

| 90 graden side freeskop (1 stasjon) | ER40/4000rpm | ER40/4000rpm | ER40/3000rpm | ER40/3000rpm | ER40/4000rpm | ER40/4000rpm | |

| Oar | Totale kapasiteit | 48 kW | 55 kW | 34KW | 34KW | 48 kW | 55 kW |

| Machine tool netto gewicht | Oer 9000 kg | Oer 11500 kg | Oer 7000 kg | Oer 7800 kg | Oer 9000 kg | Oer 11500 kg | |

| Machine grutte (lengte × breedte × hichte) | 7000×2300×2550 | 8500×2300×2550 | 6000 × 2300 × 2550 | 6500×2300×2550 | 7000×2300×2550 | 8500×2300×2550 | |

Konfiguraasje Features

Spindle

Stypje hege-precision en swiere-duty cutting te fergrutsjen produktiviteit.

Turret

Ferbettert yndeksearring betrouberens en soarget hege rigidity.

Systeem

Standert FANUC F Oi-TF Plus CNC-systeem, hege ferwurkingsprestaasjes hege bestjoeringsnivo, heech gebrûksgemak.

Hege rigidity

Heavy-duty CastIron Base En Components, Sterke shock absorption en hege stabiliteit.

Ball Screw

Skroef foarspanning, backlash en ferlinging fan temperatuerferheging wurde foarôf eliminearre.

Roller Linear Guide

Arc cutting, bevel cutting, en unifoarm oerflak textuur. Universele hege snelheid rotaasje.